Why AI Projects Fail (and which ones don’t)

- Celso Rangel

(Why AI projects fail (and which ones don’t) is an article based on a presentation I gave at the SCHULLER&Company AVEVA DACH User Meeting 2025 in September 2025. Reach out to us for more detail!)

95% of AI pilots are failing

That’s the number from a recent MIT study. The study had a small sample size, and results vary across industries. It’s early days for this kind of analysis. But in my personal experience talking to several engineering firms, the number isn’t far off.

What do we mean by failure? I would define failure as a negative or unclear return on investment (ROI) six months after implementation. And I think most of the cases I’ve seen fit the bill.

So the big question is: why are we not able to harness the power of AI in engineering?

The state of AI in Engineering

Let’s consider the current status of AI implementations in engineering firms. Most companies today are likely:

- Rolling out Microsoft Copilot across the organization.

- Building documentation search solutions, often based on internal standards or knowledge databases.

- Adopting AI for support tasks like meeting notes, translation, or transcription.

Which are all great things and can be very useful. But you know what’s telling with this picture? Where do you see we are not using AI?

Engineering. Procurement. Construction. Construction Management. Surprisingly little AI adoption there.

Said nobody ever.

And these are the areas that define our actual value output.

I’ve never seen a project manager or CEO walk into an all-hands meeting and say: “Guys, we need to talk because last year we wasted too much time taking meeting notes. This is why our company isn’t doing well.” It just doesn’t happen.

The fact is: as long as we optimize conveniences and ignore our core business processes, we’ll never see a meaningful return on our AI investments.

Why do engineering firms struggle to get value from AI?

I see three big reasons why AI is failing to make a big impact in engineering.

Risk and Safety Concerns

EPC firms are very conservative by nature. When considering AI solutions, a lot of questions pop up which slow down adoption of these tools.

- Could AI make a mistake in a design?

- How do we ensure results are correct?

- Is our data secure?

These are valid concerns. The nature of our business is dealing with dangerous things: tons of steel, high-pressure piping, hazardous chemicals, you name it. Of course people are reluctant to apply new tools to critical processes.

The One-Size-Fits-All Illusion

AI is a broad term, and it doesn’t always mean the same thing. People think, “Hey, I want to implement AI into my company,” like AI is one thing. As if you could walk into a minimarket and say, “could you give me some AI?” and they hand you a USB stick that you plug into your company’s main server and—done!

Of course it doesn’t work like that. We cannot have one solution to fit all because different processes require different solutions.

Misplaced Focus

This is the big one. Too often, companies apply AI tech-first instead of problem-first.

We know there’s AI to take meeting notes—lots of solutions for this—so great, use it! But is that the problem holding your company back?

The focus has to be the other way around. You have to look at your company, find your processes, and ask: where are we struggling? Where could AI help us improve our business?

How to find value using AI in our core business?

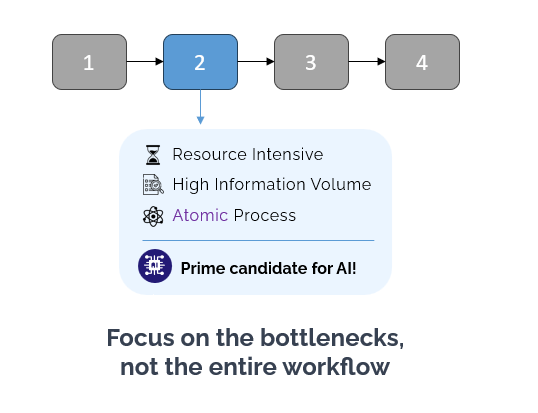

To find value in your core business, you need to identify the steps in your workflow that are prime candidates for AI.

The rationale is we need to find processes in our workflows where humans are inefficient, but AI could make a big productivity gain—and we look for individual processes, not overarching plans (this is the one-size-fits-all we are trying to avoid.)

Look for processes with these three characteristics:

Find the right processes to implement AI solutions.

Resource Intensive

They take a lot of human capital and time to get done. These are the bottlenecks in your workflow. Anywhere where you’re spending a lot of hours and people should ring an alarm: can AI make this better?

High Information Volume

Human beings are not good at handling large amounts of information at once. If your process requires high information volume, by definition it will have a lot of human error. AI can help.

Atomic Process

The process we are trying to improve has a very clear, defined start and end, input and output. If you know what you expect to get in and what’s the expected output, and it doesn’t depend on other processes, that’s excellent for AI. Because then you know how to check whether the AI is giving you the right result.

When you find a process that combines high information volume, atomic boundaries, and resource intensiveness—that’s your perfect candidate to start considering implementing AI there.

A Real Example That Delivers Immediate ROI

Let me give you an example of an atomic process we’ve faced. Think about the end of the engineering phase. Your vendor data floods in shortly before you have to issue everything to construction. You’re getting:

- Catalog data from valve and instrument suppliers

- Equipment drawings

- Tons of different specifications

Typically what happens? Crunch time. You have to read all this data and edit your design. If you get a valve drawing from a manufacturer, you need to parse it, check dimensions and ratings, adjust your designs, and rerun your drawings. This creates high error rates and non-conformities.

This process is:

- Resource-intensive (many hours of skilled labor)

- High volume (hundreds of documents and data points)

- Atomic (clear input: vendor drawings; clear output: updated, verified designs)

AI can make an immediate difference: automatically extracting vendor data, cross-checking it with the design, and verifying consistency.

Want to know the ROI? It’s simple math:

Number of vendor drawings × Hours saved per drawing × Cost per engineering hour = Money saved per project

That’s immediate, measurable value. For a typical project with 500 vendor drawings, saving 2 hours per drawing at $150 per hour, you’re looking at $150,000 saved. Per project.

Now that is something I can imagine your PM bragging about in an all-hands.

How to Be in the 5%

The path from the 95% to the 5% isn’t complicated. Map your core business workflows: engineering, procurement, construction. Find where work piles up and apply the three criteria: resource-intensive, high information volume, atomic process. When you get three yeses, you’ve found your target.

Start with one process. Measure everything. Prove the ROI. Then scale.

AI isn’t failing because the technology is weak. It’s failing because companies chase shiny tools instead of tackling real bottlenecks. Flip the question from “Where can I use AI?” to “Where am I bleeding time and money?”

That is being problem-first rather than tech-first. Do that, and the question isn’t whether AI works. It’s whether your competitors are catching up.